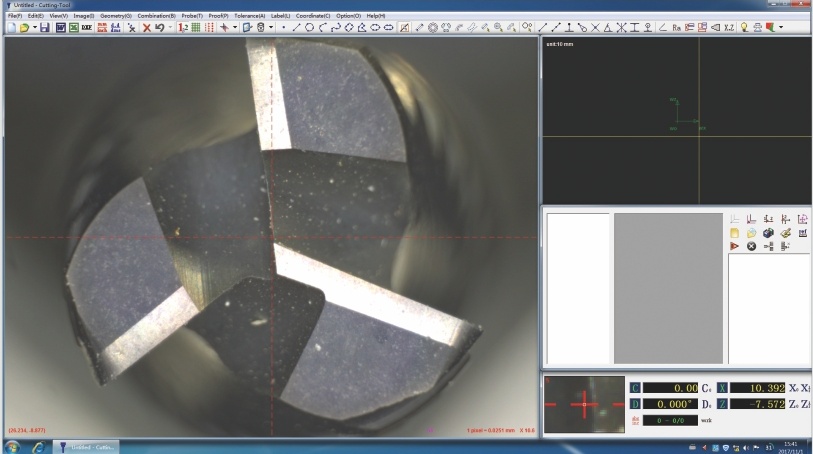

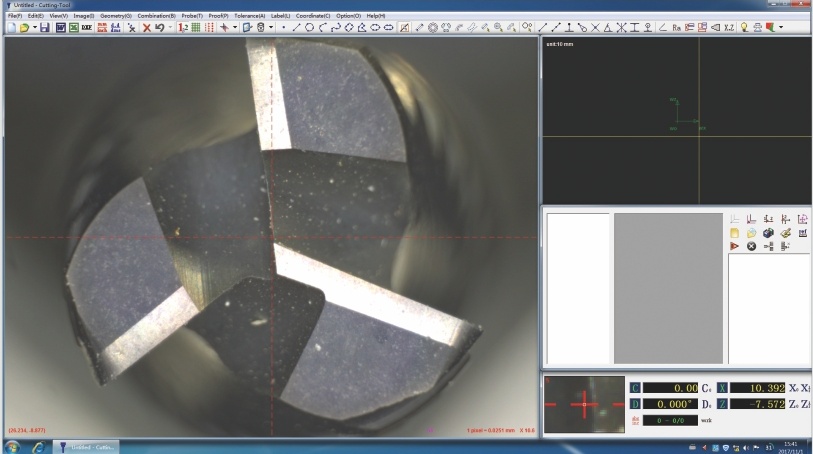

Milling Tool Inspection System Tool VMM Machine

Product Application

The UNIMETRO RANGER600 Tool VMM Machine is the universal measuring machine for drills, milling cutters and

counters and countersinks under Flexible illuminating system.

Thanks to the compact design and great stability, The RANGER600 can

be employed in the metrology room, receiving inspection, or

directly in production. The RANGER600 Tool Inspection system is

configured with SMARTOOL universal measuring software, which makes

it the best instrument for all types of metal cutting tools,

starting from fast checking of single criteria, such as the outer

contour or angles, to complete control of special tool geometries.

Users can easily achieve a PUT-MEASURE-ANALYSE measuring process

with the RANGER600.

Tool VMM Machine Advanced Design

--Ergonomic design and solid construction.

--HD image capturing and display combination, also microscope

magnification level is optional.

--High accuracy encoder is embedded in the rotary table, offers

precise angle location for users.

--Multiple section programmable LED ring light for surface

illumination, also including contour lighting and free angle

auxiliary light for standard features.

--SMARTOOL measuring software offers specific measuring function

for cutting tools.

Parameters

| SPECIFICATIONS FOR Milling Cutter Measuring System |

| X axis travel | 80mm | |

| Y axis travel | 60mm | |

| Z axis measuring range | 60mm | |

| Max tool Diameter | 20mm (optional 30mm) | |

| Max tool length | 200mm (optional 350mm) | |

| Working distance | 90mm | |

Lens | 0.7X-4.5X dented zoom lens |

Camera | 2M pixel HD camera/5M pixel HD camera(Optionsl) |

Linear scale resolution | 0.0001mm |

Magnification | 12.6X-79.2X/25.2X-158.4X(optional) |

Field of view | 27*20mm~4.3*3.3mm/13.5*10mm~2.3*1.6mm(Optional) |

Measuring accuracy | X~Y,(2.5+L/100)μm,L is the measured length |

PC | ALL-IN-ONE PC system, Windows 10 OS, with 24" LCD monitor |

Illumination system | 8 sections LED ring light, contour light and flAexible auxiliary

light, all software control and programmable. |

Input format | DXF files |

Output format | EXCEL, DXF |

Descrition

Tool VMM Machine Multiple Angles Measuring

For a more fast and precise tools angle location during the

measuring process, the rotary table of the RANGER600 offers 2

mechanical fixed angles, 0 degree and 90 degrees. At the 0 degree

position users are able to measure Tool End, Tool End - Center

shaft, Tool End - front angle, etc. And 90 degrees position is

available for Helix angle, Axial Front angle, First Rear angle,

Second Rear angle and Tilting Edge angle, etc.

If other angle location should be required, users can also use the

accurate encoder which is embedded in the rotary table to obtain.

The angle reading is display in the software.

Tool VMM Machine Standard Accessories

Free angle auxiliary light

A dimmable additional light is available on a flexible arm. Which

helps the users to get a local enhance image.

Contour light module

The RANGER600 is including a parallel light path contour LED light

module, which is movable along the X axis direction, offers the

best image and sharp edge of the object view to the user when

measuring the contour of the tool.

Base table

Solid standing work station with practical and open-view storage

space for storage of materials and tools.

Tools holder

A multiple section tools holder is embedded at the side of the

machine. Users can hold all the tools in order for preparation to

avoid confusion.

Tool VMM Machine SMARTOOL Measuring Software

Leading cutting tools measuring solution

The SMARTOOL Cutting Tools Measuring Software is developed based on

high accuracy optical and digital measuring technology, it is easy

and intuitive to operate and offers numerous measuring and

evaluation algorithms specifically for tools manufactured or

sharpened in grinding business.

Sharp,high-contrast views at all magnification.Allmagnification are

calibrated.

High zooming level allows analysis of even the smallest surface

details or the inspection of micro-tools.

Intuitive and easy-operating software interface-for fast and easy

measurement application,all function keys and operation panel are

graphical,and the automatic edge detection function helps to

eliminate the measuring result difference of different operators.

Free switch between obiect image view and real time contour curve

view-users are able to get the observation and measure the max

edges of the tools during dyamic rotating process.Advanced

calibration and compensation process-the SMARTOOL software offers

advanced calibration and compensation function,highly increase the

accuracy of the measurement.

Measuring Capability

Helix Angle Axial Front Angle First Rear Angle

Tool End Tool End - Center Shaft Tool End - Front Angle

Company Information

Our Client&Agent

| FAQ |

|---|

Q1: Are you a factory or trading company ? Q1: Are you a factory or trading company ? |

A1: We are a factory and giving you the quickest reply in 24

hours. A1: We are a factory and giving you the quickest reply in 24

hours. |

|---|

Q2: What's your company mainly in? Q2: What's your company mainly in? |

A2: We are mainly produce Vision measuring machine,Coordinate

measuring machine ,CMM&VMM fixturesetc. A2: We are mainly produce Vision measuring machine,Coordinate

measuring machine ,CMM&VMM fixturesetc. |

|---|

Q3: How to Choose the Appropriate Specification? Q3: How to Choose the Appropriate Specification? |

A3: As long as you tell us variety and size of product to be

measured, our professional team would advise you of measuring

instrument of suitable specifications. A3: As long as you tell us variety and size of product to be

measured, our professional team would advise you of measuring

instrument of suitable specifications. |

|---|

Q4: Do you accept customized service? Q4: Do you accept customized service? |

A4: Be sure! We can provide not only typical machines, but also

the machines customized to customer's needs. A4: Be sure! We can provide not only typical machines, but also

the machines customized to customer's needs. |

|---|

Q5: What is your warranty period? Q5: What is your warranty period? |

A5: Our product warranty period is 1 year. Our product quality is

very stable, and we have A5: Our product warranty period is 1 year. Our product quality is

very stable, and we have

improved a lot on some breakable parts. You can rest assured of our

product quality. |

|---|

Q1: Are you a factory or trading company ?

Q1: Are you a factory or trading company ? A1: We are a factory and giving you the quickest reply in 24

hours.

A1: We are a factory and giving you the quickest reply in 24

hours.